Msc2G3:Paper

Research

Echosphere is an atmospheric stage that improves the acoustic quality for lectures. On architectural, functional, and acoustic level it enables the connection between lecturers and the audience. It is an optimized shell structure with a sound absorptive capacities, developed for Hyperbody’s gsm3 symposium at the orange hall at the TU Delft. The focus of Echospheres prototype is on combining and integrating materials, a mix of solid and plate materials in the ways of subtractive manufacturing.

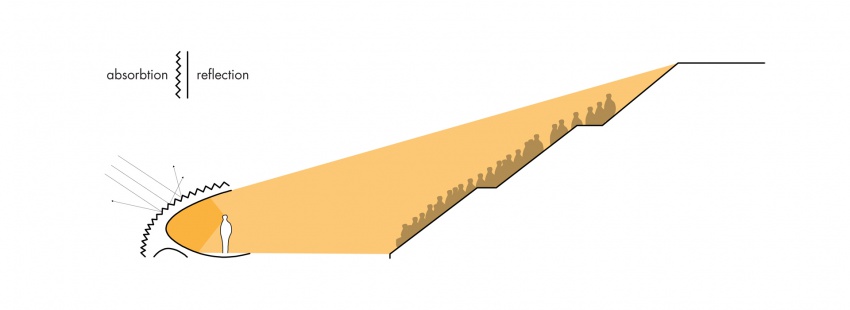

(1) Brief concept. Improve acoustic qualities of the hall.

Sound Quality

In large conference halls the sound quality is often a problem. Echosphere aims for providing a solution for the acoustics. Measurements in the orange hall in the faculty have been conducted to get the right context to calculate in with the parameters reverberation time, speech transmission index, and early reflections. The reverb is improved by adding sound absorbing material to the stage, this takes away transmission distorting long reflections. The sound absorption focuses on certain areas of the sound spectrum that correspond with speech to improve the speech transmission index. Next to these measures the shell of Echoshpere is optimized for early reflections, these can amplify the sound transmission of the lecturer towards the audience. The Porsche Pavilion by HENN (1) showed the potential of acoustic shells in an architectural way. The idea of an acoustic shell for stage design is developed in the project by using two-dimensional ray tracing to get the right shape of the shell.

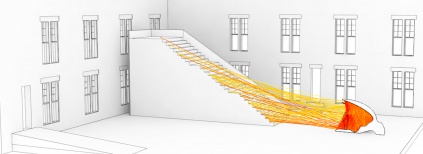

(2) Left: Acoustic shell optimization by ray tracing. Right: Porsche Pavillion by HENN architects.

Architectural Concept

The macro geometry combines the acoustic shell with several other functions. The goal is to engage the audience with the lecturers on and around the stage. It incorporates seating areas for discussions, a corridor to the back of the stage, and a bar. Overall a smooth transition between the functions is aimed for. This means that floor, wall, ceiling, and seating area are all designed in the same system. Local variations are mainly influenced by the parameters reflectiveness, porosity, and structural optimization. The shell is constructed in a combination of cork and EPS foam. The material used for constructive parts, reflective surfaces, and vulnerable spots is EPS. Cork appears at softer places for seating and at the sound absorption areas.

(3) Several user scenarios.

Materialization

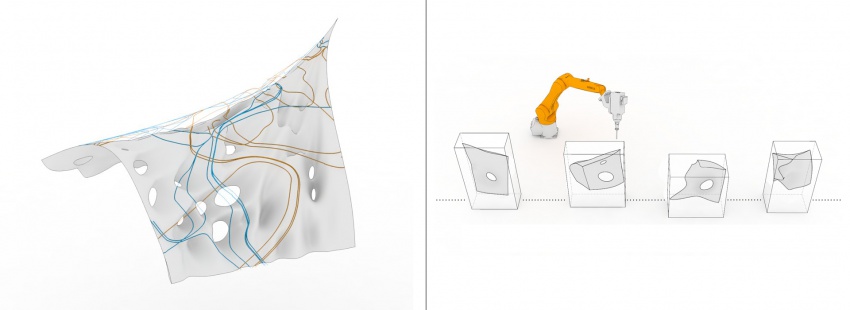

The shell is divided into several components based on topology of the design. The subtractive modelling of the EPS is based on a structural optimization and sound reflection. Force lines morph the surfaces defining the EPS into position. The spots which need to be reflective stay in their original position. This morphing takes place in a three-dimensional context, to keep design continuity over the components. Porosity is created at the spots where extra light is needed. On these spots the inner and outer surfaces intersect to create holes in the blocks. For the architecture this means constant transitions of smooth surfaces and scaped surfaces with hills, holes and valleys.

(5) Left: scaping by structural optimization. Right: Production process.

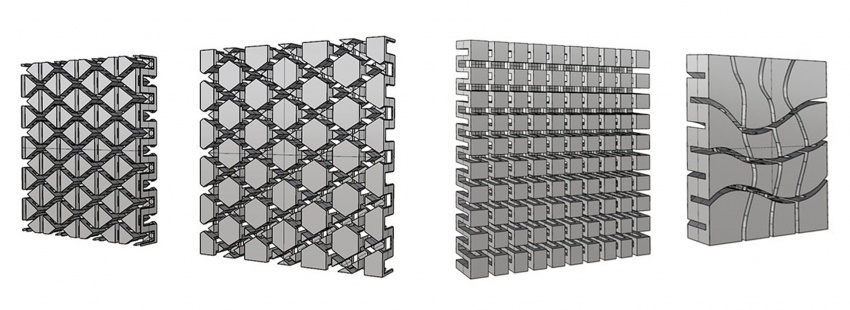

In between the EPS is a double curved cork surface. The cork has a morphed grid on it that enables bending behavior, sound absorption and sound diffusion. The hills and valleys of the EPS structure inform the morphing of the cork grid, componential logic of the cork, and thickness of the cork plates. To be able to produce the cork from a plate material, the 3D model is mesh unrolled. The local grid pattern of the macro geometry is uv-projected onto the unrolled surfaces to enable a seamless transition and high accuracy. The grid defines a fast producible carving pattern, intersecting ‘v-shape’ sections are cut out of the cork. The pattern creates possibilities for bending and additional porosity.

(6) Left: Mesh unrolling and mapping uv-pattern. Right: Cork production.

Design and prototyping

Several prototypes have been made on the cork panels. These models where conducted in Styrofoam, cork and flexible SLA. The first prototypes where made to research the influence of patterns on bending behavior; hexagonal, triangular and morphed grid structures where tested. Grid structures tend to have the best opportunities for bending. This can be explained by the fact that the curves are uninterrupted and perpendicular.

(7) Design iterations in cork patterns.

(8) Left: Production process and result of first prototype. Right: Testing in Styrofoam.

Another prototype is laser cut and elaborates flat cork attachment. The edges of components are pushed into a 180° connection by finger joints. Fitting the components is due to both approximation of the double curvature in single curved surfaces and material properties of the cork. The unrolling method used in this prototype is not completely accurate. Architecturally this prototype shows smooth seams that blend into one larger surface.

(9) Second prototype: pushing cork into position.

The Corkigami chair by Carlos Sortega (2) show the flexibility of cork in a single curved way. The way the cork is treated can be compared to tailoring. The chair is made out of a single piece that is curved over three lines and attached in one spot. The wood pavilions of Achim Menges(3) explore the idea to build a double curved structure out of single curved wood surfaces. To achieve this he uses the techniques of pulling the wood in position by finger joints and unrolling.

(10) Left: Corkigami chair by Sortega, right wood pavillion by Menges.

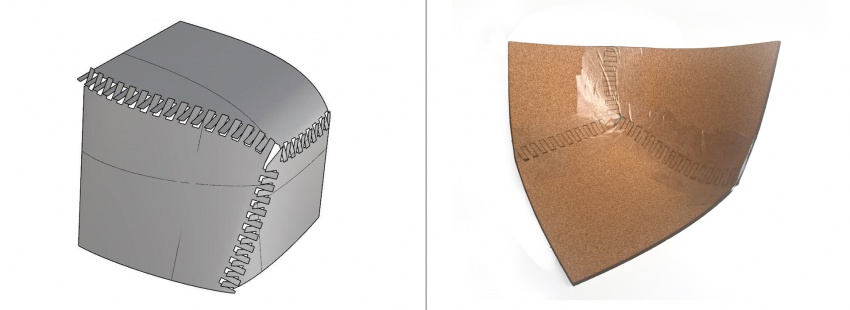

The last prototype was printed to test the accuracy of 3D mesh unrolling and the 3D to 2D mapping of data to it. The flexible SLA represents the cork, the solid the EPS. The thickness of the cork plates is determined by the distance to EPS blocks in the normal direction. This enables a high predictability in the behavior of the cork and the pattern. This gives a range of possibilities to fit cork and EPS from perpendicular to normal direction.

(11) 3D print prototype of cork-fitting.

Most architecture regarding unrolled double curved plates try to achieve it by using single curved approximation. This project tries to bring these folding techniques a step further, without using molds or doing concessions on the individual pieces of the surfaces. By using a slightly flexible material, in this case cork, by unrolling it with double curved mesh unrolling, by carving on the right spots, and attaching material in flat connections it enables the surfaces to have an accurate and continuous result. For the architecture this means the possibility of more fluid shapes and smooth component divisions.

Connecting

Echosphere connects people at conferences in inconspicuous ways. It enables the conference to have a fluid exchange of information due to the optimal acoustic circumstances. During lectures it’s an acoustic shell, in between lectures it hosts discussions or serve as meeting place. The audience is invited to visit and explore the shell in a constant transition of functions and materials.

On material level techniques of two worlds come together in Echosphere, unrolling architecture and solid organic architecture. It’s a research on integrating different computational models and architectural aspects into one piece of architecture. These systems react to each other, connect and disconnect at certain points. Rather than the use of a detail in a variable system, it embeds a system that produces variable details. The architectural language becomes one of gradual material changes, providing an ever-changing experience of situations.

References

(1) Porsche Pavillion by HENN Architects

(2) Corkigami Chair by Carlos Sortega

(3) ICD/ITKE Pavillion 2015-2016 by Achim Menges