Difference between revisions of "Msc2G3:Group"

| Line 23: | Line 23: | ||

<img src="http://vanderdoorn.eu/overige/160614divisioncomponents.gif" width="850px" heigth=""> | <img src="http://vanderdoorn.eu/overige/160614divisioncomponents.gif" width="850px" heigth=""> | ||

</html> | </html> | ||

| − | |||

| − | |||

| Line 41: | Line 39: | ||

</html> | </html> | ||

| − | [[File:Fabricationweek - 2 components come together with interlocking system-03. | + | [[File:Fabricationweek - 2 components come together with interlocking system three-03.png|850px]] |

Revision as of 17:19, 21 June 2016

Picture of all the scales here.

Concept

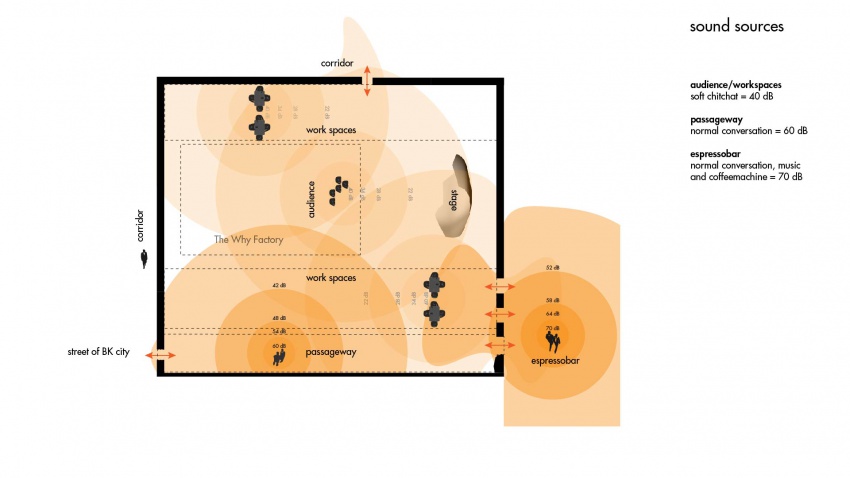

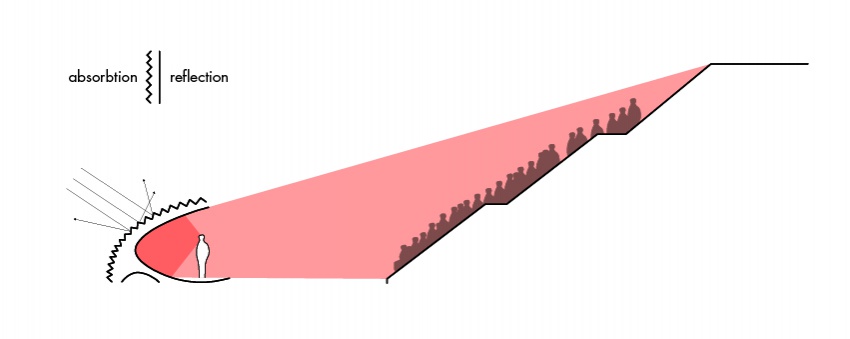

This part of the stage will focus on acoustics. To host a better exchange of knowledge and ideas, the connection between the audience and speakers should be as fluent as possible. Acoustic analysis, of both the shape and surrounding, informs the model which results in an optimized shape for the acoustic conditions.

To improve the acoustic quality during the symposium this part of the stage will absorb, diffuse or reflect soundwaves. The inside shell focused and optimized for to establish a direct connection between the whole audience and the speaker.

Analysis

Macro

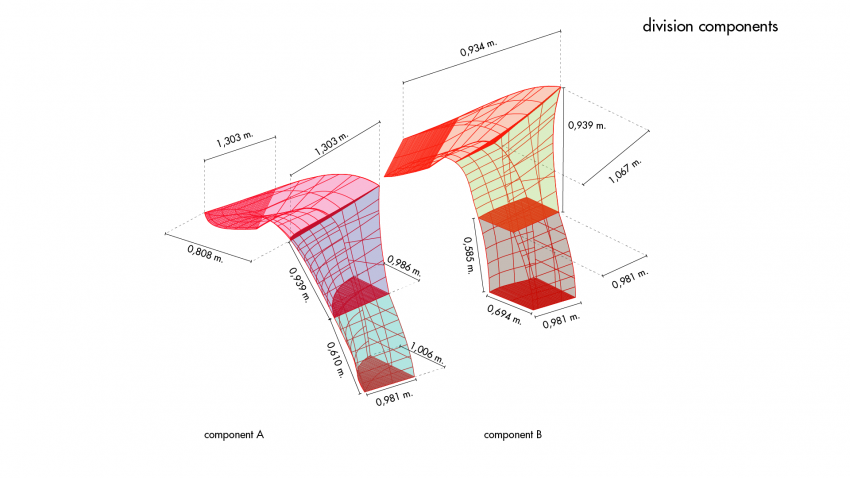

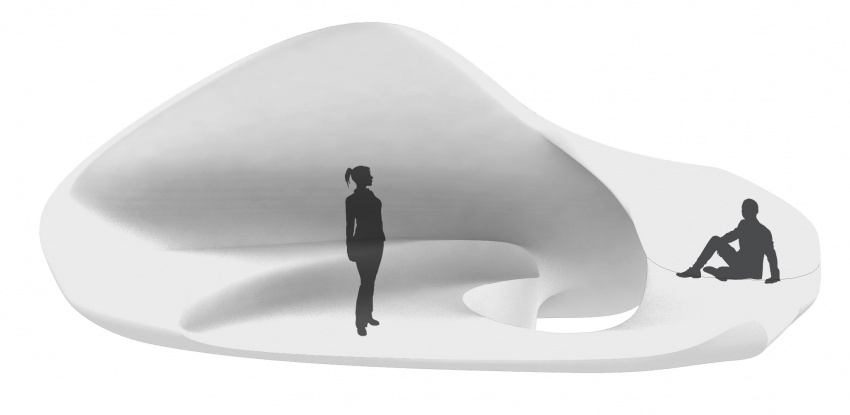

The macro shape of the shell is based on various inputs. First there is a main design, that exists of a corridor and the notion of a shell like structure. This shape is affected by the landscape that is formed, based on ergonomic sections. Then the shape is optimized for the reflection of sound from and towards the audience. Both the horizontal and vertical sections are tweaked to allow the geometry to work as a single sound amplifying shell. The floor, seating and ceiling are a continuous shell that works as one.

The macro shape of the shell is based on various inputs. First there is a main design, that exists of a corridor and the notion of a shell like structure. This shape is affected by the landscape that is formed, based on ergonomic sections. Then the shape is optimized for the reflection of sound from and towards the audience. Both the horizontal and vertical sections are tweaked to allow the geometry to work as a single sound amplifying shell. The floor, seating and ceiling are a continuous shell that works as one.

The shell is optimized for a evenly spreaded sound reflection towards the audience. This way the first 15ms of the hull of the speaker's voice are received more clear by the audience.

Meso

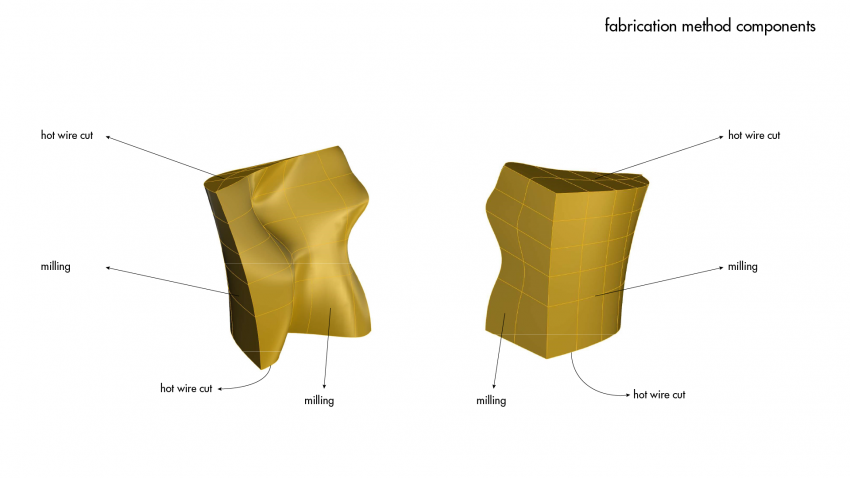

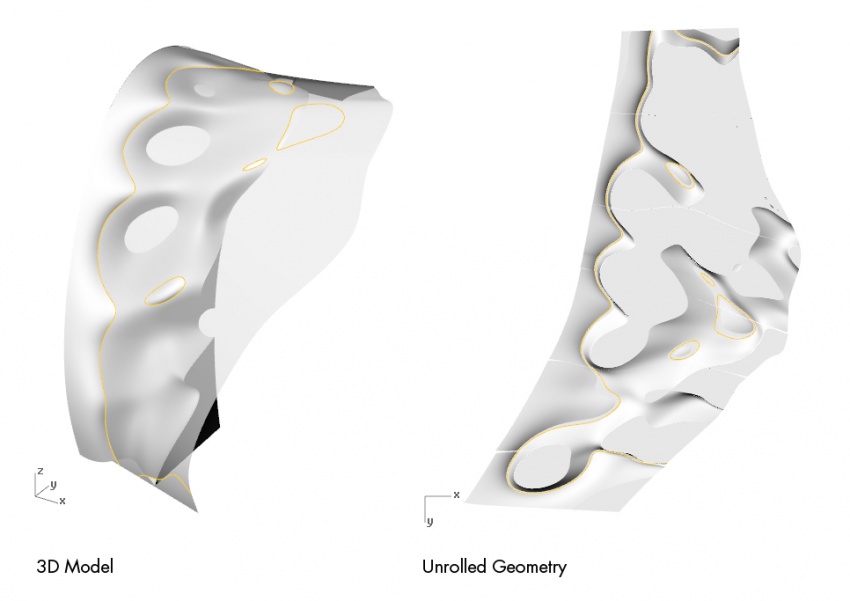

The construction consists out of a cork shell on the inside that is broken up by the eps construction where possible to generate larger surface for sound absorption. This basically means the front and back side have a different appearance by the same cork system.

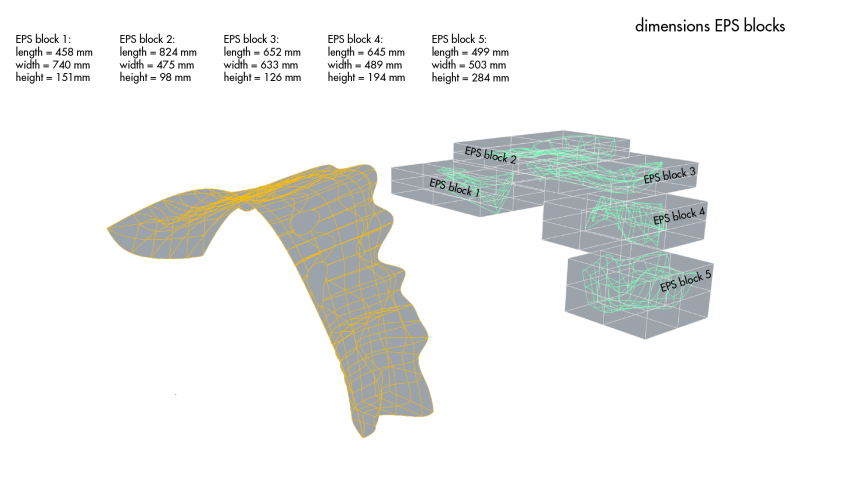

EPS

Cork

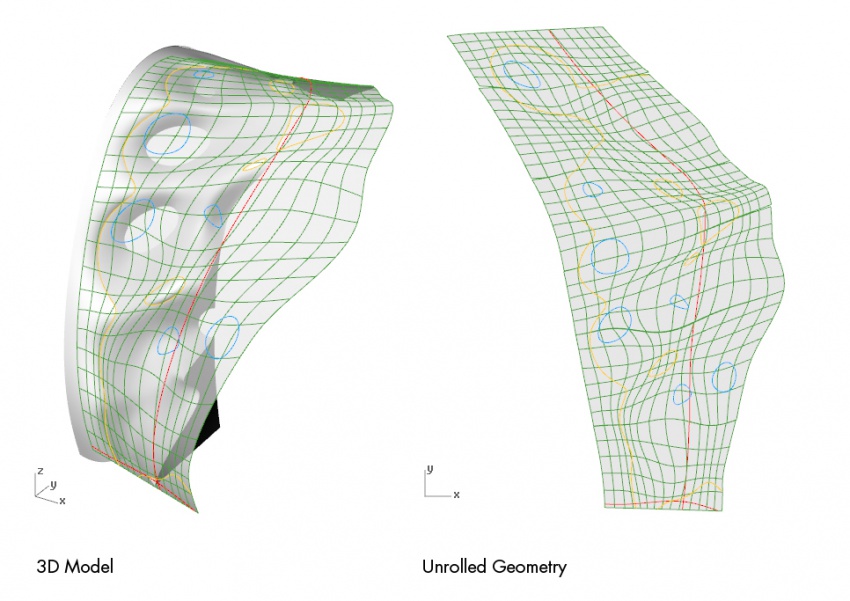

The information that is needed to produce the cork comes from a 3D model. Cuts with the EPS are taken to project a pattern, heightmap and cutting plane on the production files.

The information that is needed to produce the cork comes from a 3D model. Cuts with the EPS are taken to project a pattern, heightmap and cutting plane on the production files.

Micro

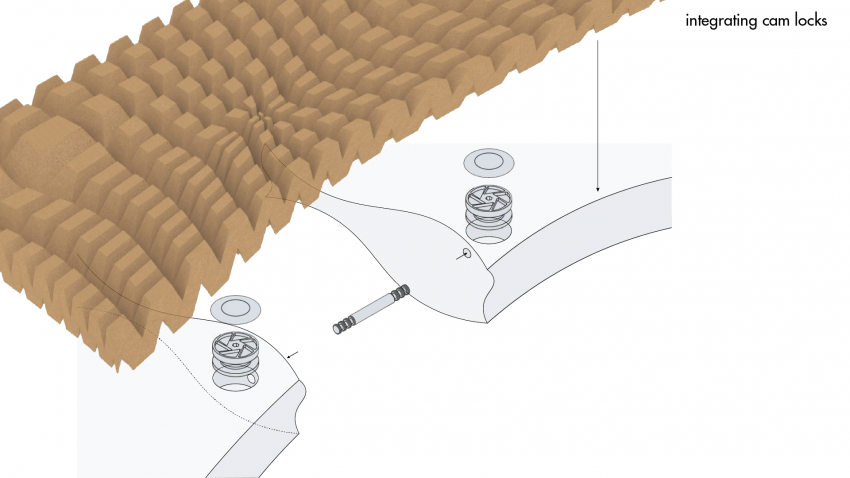

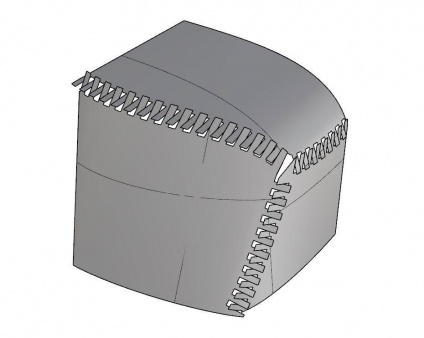

The inner shell is made out of cork. If the thickness and density of the cork is right the material is able to bend as a single curved material. By making fingerjoints and flattening these a geometry is able to approach a double curved surface.

Prototype of transition from single curved elements to double curved surface.