|

|

| (137 intermediate revisions by 4 users not shown) |

| Line 1: |

Line 1: |

| | __NOTITLE__ __NOTOC__ | | __NOTITLE__ __NOTOC__ |

| | | | |

| | + | <html> |

| | + | <style> |

| | + | .header-background{background-image: url("http://gsm.hyperbody.nl/images/5/50/20160701_Group3_background-wiki.jpg");background-color: #cccccc;width:850px;height:300px;background-size: 100% auto; background-repeat: no-repeat;} |

| | + | .header-content{position:relative;bottom:50px;left:0px;} |

| | + | .button-container{width:150px;height:50px;float:left;color:white;text-align:center;float:right;} |

| | + | .bottom-container{position:relative;width:850px;height:10px;float:left;background-color: rgba(255, 128, 0, 0.7);bottom:10px;} |

| | + | .button{width:140px; height:30px; bottom:10px;background-color: rgba(50, 50, 50, 0.23);padding-top:10px;} |

| | + | a.nav-link:link,a.nav-link:visited{text-decoration:none;font-weight:bold;color:white} |

| | + | a.nav-link:hover,a.nav-link:active{text-decoration:none;font-weight:bold;color:#FF8000;} |

| | + | a.nav-link-active:hover,a.nav-link-active:active{text-decoration:none;font-weight:bold;color:#000;} |

| | + | .left-filler{width:230px;height:40px;float:left;} |

| | + | .hidden{visibility:hidden;} |

| | + | .tab-active{background-color:rgba(255, 128, 0, 0.7);} |

| | + | </style> |

| | + | <!-- Navigation --> |

| | + | <div> |

| | + | <div class="header-background"> |

| | + | </div> |

| | + | <div class="header-content"> |

| | + | <div class="left-filler"> |

| | + | </div> |

| | + | <div class="button-container"> |

| | + | <div class="button"><a class="nav-link" href="http://gsm.hyperbody.nl/index.php?title=Msc2G3:Paper">Research</a></div> |

| | + | </div> |

| | + | <div class="button-container"> |

| | + | <div class="button"><a class="nav-link" href="http://gsm.hyperbody.nl/index.php?title=Msc2G3:Production">Production</a></div> |

| | + | </div> |

| | + | <div class="button-container"> |

| | + | <div class="button"><a class="nav-link" href="http://gsm.hyperbody.nl/index.php?title=Msc2G3:Materialization">Materialization</a></div> |

| | + | </div> |

| | + | <div class="button-container"> |

| | + | <div class="button tab-active"><a class="nav-link nav-link-active" href="http://gsm.hyperbody.nl/index.php?title=Msc2G3:Group">Concept</a></div> |

| | + | </div> |

| | + | <div class="bottom-container"> |

| | + | </div> |

| | + | </div> |

| | + | </div> |

| | + | </html> |

| | + | <i class="hidden">Text</i> |

| | | | |

| − | [[File:Perspective.png| 850px]]

| + | =='''Echosphere'''== |

| | | | |

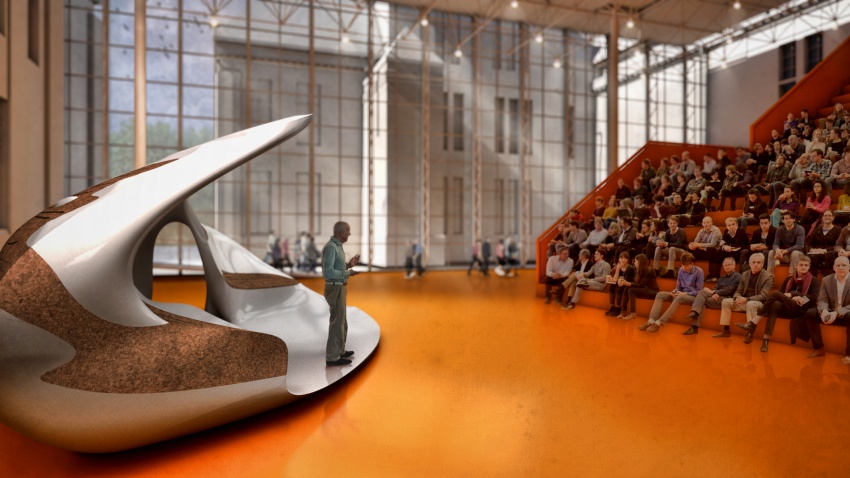

| − | =='''Concept'''==

| + | ''Echosphere'' is an atmospheric stage that improves the acoustic quality for lectures. On architectural, functional, and acoustic level it enables the connection between lecturers and the audience. It is an optimized shell structure with a sound absorptive capacities, developed for ''Hyperbody’s gsm3'' symposium at the orange hall at the ''TU Delft''. The focus of Echospheres prototype is on combining and integrating materials, a mix of solid and plate materials in the ways of subtractive manufacturing. |

| − | <p>To host a better exchange of inspiring ideas and knowledge during the symposium between the people involved, our part of the stage will be focused on improving the sound quality.

| + | |

| | | | |

| − | Acoustic analyses will inform our model which results in different geometrical configurations and different material characteristics of unique components. As a result, the generated geometry regulates acoustic performance according to the desired criteria and the acoustic demands of the stage.

| + | [[File:20160630 Group3 Concept Echosphere.png|850px]] |

| | | | |

| − | </p>

| + | '''Architectural use''' |

| | | | |

| − | [[File:PositionInStage.jpg| 850px]]

| + | The macro geometry combines the acoustic shell with several other functions. The goal is to engage the audience with the lecturers on and around the stage. It incorporates seating areas for discussions, a corridor to the back of the stage, and a bar. |

| | | | |

| − | <p>To improve the acoustic quality during the symposium our part of the stage will absorb, reflect or amplify soundwaves. Our model will be informed by these soundwaves which results in different responses according to the desired requirements. | + | <html> |

| | + | <iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Concept_Architectural.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> |

| | + | </html> |

| | | | |

| − | When the lecturer is speaking our model will absorb all the background noises of the Orange hall, so the lecturer and the audience won’t be distracted from the lecture.

| + | [[File:Echosphere final.jpg|850px]] |

| − | When there will be questions from the audience the model will reflect the sound in such a way that the soundwaves will be directed to the lecturer, so he or she can hear it more clearly.

| + | |

| − | In the case of a discussion on stage, the model will amplify the discussion for a better audibility for the audience.

| + | |

| | | | |

| − | </p>

| |

| | | | |

| − | [[File:Sound.png| 850px]]

| + | '''Improving acoustics''' |

| | | | |

| − | =='''Components'''==

| + | In large conference halls the sound quality is often a problem. Echosphere aims for providing a solution for the acoustics. It's an optimized shell structure that combines sound absorption and scattering in an informed way. |

| | | | |

| − | <p>Acoustic components | + | <html> |

| | + | <iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Concept_Sound.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> |

| | + | </html> |

| | | | |

| − | - '''Sound reflectors:'''

| + | <html><iframe width="850" height="478" src="https://www.youtube.com/embed/pHzN3pHoWbs" frameborder="0" allowfullscreen></iframe></html> |

| − | Reflect sound waves in such a way that the angle at which the wave approaches the surface equals the angle at which the wave leaves the surface. By sound source localization techniques we aim to direct the soundwaves to a specific focus point.

| + | |

| | | | |

| − | - '''Sound absorbers:'''

| |

| − | These components are taking in sound energy when sound waves are encountered. Depending on the absorption coefficient and the depth of the material these components can absorb specific frequencies derived from background noises in the Orange hall.

| |

| | | | |

| − | - '''Speakers:'''

| |

| − | An embedded speaker in a component converts an electrical audio signal, derived from the lecturer into the corresponding sound.

| |

| | | | |

| − | Other components

| + | =='''Team'''== |

| | | | |

| − | - '''Structural components''':

| + | <gallery style="text-align:left" font-size="80%" mode="packed-hover" heights="190px" > |

| − | These components provide the integral support structure of the stage.

| + | File:Group3 team Daniel.jpg | Daniel Fisher d.l.Fischer@student.tudelft.nl |

| − | | + | File:Group3 team Annloes.jpg | Anneloes Kattemölle a.m.Kattemolle@student.tudelft.nl |

| − | - '''Components with embedded sensors:'''

| + | File:Group3 team Olav.jpg | Olav van der Doorn o.b.vanderdoorn@student.tudelft.nl |

| − | these components are provided with integrated sensors. These sensors will not only gather acoustic data for our part of the stage, but will also collect information for the other groups.

| + | File:Group3 team Benjamin.jpg | Benjamin Kemper b.n.Kemper@student.tudelft.nl |

| − | | + | </gallery> |

| − | - '''Projector & display components:'''

| + | |

| − | The integrated projector will project data onto the surface of another component of the stage.

| + | |

| − | - the name and the topic of the lecturer

| + | |

| − | - images/slideshows/videos that support the lecture

| + | |

| − | - time table information during breaks

| + | |

| − | - etc.

| + | |

| − | </p>

| + | |

| − | | + | |

| − | [[File:Components.png| 850px]]

| + | |

| − | | + | |

| − | =='''Construction'''== | + | |

| − | <p>Below is shown the construction of the sound absorbing component. Embedded sensors in other components will collect and send data to these sound absorbing components. To optimize the acoustic qualities this data will be converted in a specific configuration of the tessellated surface of the sound absorbing components. Actuators connected to a frame in the back of the component will be activated in order to move the panels. This creates space in between the panels. Soundwaves will enter these gabs and be caught by the absorbing material integrated in the component.

| + | |

| − | </p>

| + | |

| − | | + | |

| − | [[File:ConstructionDetail.png | 850px]]

| + | |

| − | | + | |

| − | <p>Manufacturing:

| + | |

| − | From the analysis of the measurements’ results derive the design rules of the soundwaves, which are then incorporated into the design process through parametric modelling.

| + | |

| − | Then our parametric files will be loaded into the CNC milling machine for production. Since our details require a slot into the side of the panels we will need a 5 axis milling machine. The series of steps needed to produce the unique components is highly automated and produces a part that closely matches the original CAD design.

| + | |

| − | After tagging all the unique components they will all be ready for easy assembly. For assembling the components we thought of a smart interlocking system. A possible option could be that we create a topological surface of the components so you only have to stack them on each other. We could also think of a clicking system to interlock the components with additional elements. But of course we could also think of using nuts and bolts to keep the components together.

| + | |

| − | | + | |

| − | </p>

| + | |

| − | | + | |

| − | [[File:ProductionChain.png | 850px]]

| + | |

| − | | + | |

| − | =='''Prototype'''==

| + | |

| − | <p>The prototype shows a smaller cell of the complete cell structure. In this case the absorptive function was tried to work out in 1:1. Sonic waves from the surrounding will be reflected when the cell is closed. Due to opening the panel structure in front, seams increase and sonic waves will be absorbed through sound absorbing material in the cell.

| + | |

| − | The in various sections divided front can be pushed and pulled by linear actuators. The panels are connected to an elastic fabric in a sandwich construction. The fabric allows the panelized structure to contract or expand and moves the parts back to its original place, when no force is applied.

| + | |

| − | To get a fast result, the cell walls were 2D lasercut and the structure is actuated manually with six sticks on the back.

| + | |

| − | | + | |

| − | </p>

| + | |

| − | | + | |

| − | [[File:Prototype.png | 850px]]

| + | |

| − | <p> The picture shows the first prototype of a sound absorbing cell.</p>

| + | |

| − | | + | |

| − | | + | |

| − | =='''Optimization for sound scattering'''==

| + | |

| − | | + | |

| − | <html><iframe width="420" height="300" src="https://www.youtube.com/embed/oF_TsR4q0Ck" frameborder="0" allowfullscreen></iframe></html>

| + | |

| − | | + | |

| − | <p> Trying to optimize the structure for scattering sound instead of focussing it. Below are two other possible outcoming, based on different rules.</p>

| + | |

| − | | + | |

| − | [[File:160428 G3 Outcome scattering1.jpg | 850px]]

| + | |

| − | | + | |

| − | =='''Optimization for reflection'''==

| + | |

| − | | + | |

| − | [[File:060428_reflection_03.JPG | 850px]]

| + | |

| − | | + | |

| − | [[File:060428_reflection_01.JPG | 850px]]

| + | |

| − | | + | |

| − | [[File:060428_reflection_02.JPG | 850px]]

| + | |

| − | | + | |

| − | [[File:060429_reflection_04.JPG | 850px]]

| + | |

| − | | + | |

| − | <p>Here one can see the optimal relfection in the shell. The calculated spots of the input geometry will not merge to another shape. Due to that behaviour, a sound-optimized reflective interior can be created.

| + | |

| − | </p>

| + | |

| − | | + | |

| − | =='''Optimization for structure'''==

| + | |

| − | | + | |

| − | [[File:structure.jpg | 850px]]

| + | |

| − | | + | |

| − | | + | |

| − | =='''Preparation D2RP Workshop'''==

| + | |

| − | <p>To optimize the acoustic quality of the stage, we want to use cork for our components. Next week we will experiment with this material by translating our parametric models in structural components by means of CNC milling of cork blocks and lasercutting of cork plates.

| + | |

| − | </p>

| + | |

| − | | + | |

| − | [[File:Preperation D2RP 1.png | 850px]]

| + | |

| − | | + | |

| − | | + | |

| − | [[File:Preperation D2RP 2.png | 850px]]

| + | |

| − | <p> The flowchart shows the ways we could use and reuse cork for our protoypes.

| + | |

| − | </p>

| + | |

| − | | + | |

| − | [[File:Module1 Render.png | 850px]]

| + | |

| − | | + | |

| − | [[File:Module 2.jpg | 850px]]

| + | |

| − | | + | |

| − | =='''D2RP Workshop'''==

| + | |

| − | | + | |

| − | [[File: Skketch d2RP.jpg | 850px]]

| + | |

| − | [[File:Prototype pattern.jpg | 850px]]

| + | |

| − | | + | |

| − | <p> Double curved 3D structures achieved with lasercut patterns in 2D materials.

| + | |

| − | </p>

| + | |

| − | [[File:double-curved_samples.jpg | 850px]]

| + | |

| − | | + | |

| − | | + | |

| − | <p> Material samples: cork merged to 3D.

| + | |

| − | </p>

| + | |

| − | [[File:material-samples_cork.jpg | 850px]]

| + | |

| − | | + | |

| − | <p> Design system flowchart

| + | |

| − | </p>

| + | |

| − | [[File:D2RP_-_design_system_flowchart.jpg | 850px]]

| + | |

| − | | + | |

| − | <p> Design principle

| + | |

| − | </p>

| + | |

| − | [[File:D2RP - design principle with parameters - 1-01.jpg | 850px]]

| + | |

| − | | + | |

| − | <p> Design principle with parameters

| + | |

| − | </p>

| + | |

| − | [[File:D2RP - design principle with parameters - 2-02.jpg | 850px]]

| + | |

| − | | + | |

| − | <p> Parametric design approach

| + | |

| − | </p>

| + | |

| − | [[File:D2RP - parametrical design principle 1.jpg | 850px]]

| + | |

| − | | + | |

| − | <p> Four integrated acoustical performance principles

| + | |

| − | </p> | + | |

| − | [[File:D2RP - acoustical perfomance-01.png | 850px]]

| + | |

| − | [[File:D2RP - acoustical perfomance-02.png | 850px]]

| + | |

| − | | + | |

| − | <p> Architectural concept

| + | |

| − | </p>

| + | |

| − | [[File:D2RP - architectural concept.png | 850px]]

| + | |