Difference between revisions of "Msc2G3:Production"

From gsm

(→Production) |

(→Production) |

||

| (21 intermediate revisions by 2 users not shown) | |||

| Line 3: | Line 3: | ||

<html> | <html> | ||

<style> | <style> | ||

| − | .header-background{background-image: url(" | + | .header-background{background-image: url("http://gsm.hyperbody.nl/images/5/50/20160701_Group3_background-wiki.jpg");background-color: #cccccc;width:850px;height:300px;background-size: 100% auto; background-repeat: no-repeat;} |

.header-content{position:relative;bottom:50px;left:0px;} | .header-content{position:relative;bottom:50px;left:0px;} | ||

.button-container{width:150px;height:50px;float:left;color:white;text-align:center;float:right;} | .button-container{width:150px;height:50px;float:left;color:white;text-align:center;float:right;} | ||

| − | .bottom-container{position:relative;width:850px;height:10px;float:left;background-color: rgba( | + | .bottom-container{position:relative;width:850px;height:10px;float:left;background-color: rgba(255, 128, 0, 0.7);bottom:10px;} |

| − | .button{width:140px; height:30px; bottom:10px;background-color: rgba( | + | .button{width:140px; height:30px; bottom:10px;background-color: rgba(50, 50, 50, 0.23);padding-top:10px;} |

a.nav-link:link,a.nav-link:visited{text-decoration:none;font-weight:bold;color:white} | a.nav-link:link,a.nav-link:visited{text-decoration:none;font-weight:bold;color:white} | ||

| − | a.nav-link:hover,a.nav-link:active{text-decoration:none;font-weight:bold;color:# | + | a.nav-link:hover,a.nav-link:active{text-decoration:none;font-weight:bold;color:#FF8000;} |

| − | .left-filler{width: | + | a.nav-link-active:hover,a.nav-link-active:active{text-decoration:none;font-weight:bold;color:#000;} |

| + | .left-filler{width:230px;height:40px;float:left;} | ||

.hidden{visibility:hidden;} | .hidden{visibility:hidden;} | ||

| + | .tab-active{background-color:rgba(255, 128, 0, 0.7);} | ||

</style> | </style> | ||

<!-- Navigation --> | <!-- Navigation --> | ||

| Line 24: | Line 26: | ||

</div> | </div> | ||

<div class="button-container"> | <div class="button-container"> | ||

| − | <div class="button"><a class="nav-link" href="http://gsm.hyperbody.nl/index.php?title=Msc2G3:Production">Production</a></div> | + | <div class="button tab-active"><a class="nav-link nav-link-active" href="http://gsm.hyperbody.nl/index.php?title=Msc2G3:Production">Production</a></div> |

</div> | </div> | ||

<div class="button-container"> | <div class="button-container"> | ||

| Line 40: | Line 42: | ||

=='''Production'''== | =='''Production'''== | ||

| + | '''EPS production''' | ||

| + | |||

| + | The EPS is produced by subtractive manufacturing of EPS. For every block the minimum bounding box is used. | ||

| + | [[File:201630 Group3 ProductionEPS-01.jpg|850px]] | ||

| + | |||

| + | <b>EPS production video</b> | ||

| + | <html> | ||

| + | <iframe width="850" height="478" src="https://www.youtube.com/embed/SLOSZYcHx5Y?modestbranding=1&autohide=1&showinfo=0" frameborder="0" allowfullscreen></iframe> | ||

| + | </html> | ||

| + | |||

| + | '''Cork production''' | ||

| + | |||

| + | The cork pieces are produced on a special table. This table ensures high accuracy. The Kuka robot arm is used as 5-axis miller. | ||

<html> | <html> | ||

<iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Production_cork.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> | <iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Production_cork.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> | ||

| + | </html> | ||

| + | |||

| + | <b>Cork production video</b> | ||

| + | |||

| + | <html> | ||

| + | <iframe width="850" height="478" src="https://www.youtube.com/embed/Bm3OosrNYpY?modestbranding=1&autohide=1&showinfo=0" frameborder="0" allowfullscreen></iframe> | ||

| + | </html> | ||

| + | |||

| + | '''Prototype''' | ||

| + | |||

| + | <html> | ||

| + | <iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Production_Prototype.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> | ||

</html> | </html> | ||

Latest revision as of 01:48, 24 March 2017

Production

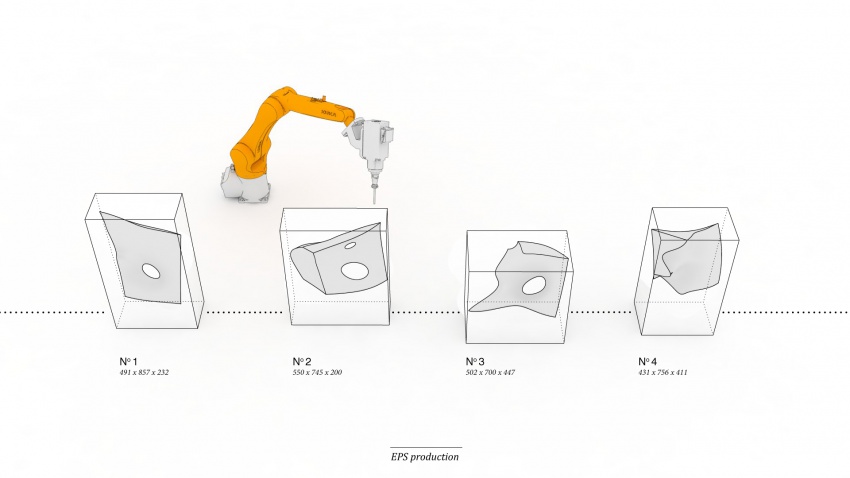

EPS production

The EPS is produced by subtractive manufacturing of EPS. For every block the minimum bounding box is used.

EPS production video

Cork production

The cork pieces are produced on a special table. This table ensures high accuracy. The Kuka robot arm is used as 5-axis miller.

Cork production video

Prototype