Difference between revisions of "Msc2G3:Materialization"

(→Materialization) |

|||

| Line 74: | Line 74: | ||

<iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Materialization_Grid.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> | <iframe width="850" height="478" src="http://vanderdoorn.eu/overige/hyperbodymsc2/Imageslider_Materialization_Grid.html" frameBorder="0" seamless="seamless" scrolling="no" allowfullscreen></iframe> | ||

</html> | </html> | ||

| + | |||

| + | '''Prototyping to design''' | ||

| + | Several prototypes have been made on the cork panels. These models where conducted in Styrofoam, cork and flexible SLA. Bending, connection and carving were tested in the prototypes. | ||

| + | |||

| + | [[File:160626 FINAL Presentation EchoSphere28.png|850px]] | ||

Revision as of 15:48, 1 July 2016

Materialization

The shell is constructed in a combination of cork and EPS foam. The material used for constructive parts, reflective surfaces, and vulnerable spots is EPS. Cork appears at softer places for seating and at the sound absorption areas.

Components

The shell is divided into several components based on topology of the design. Components are connected by an interlocking system.

Optimized structure

The subtractive modelling of the EPS is based on a structural optimization and sound reflection. Force lines morph the surfaces defining the EPS into position. The spots which need to be reflective stay in their original position.

Mapping information

Information is mapped from the 3D realm of the EPS to the 2D production files of the cork plates. The hills and valleys of the EPS structure inform the morphing of the cork grid, componential logic of the cork, and thickness of the cork plates.

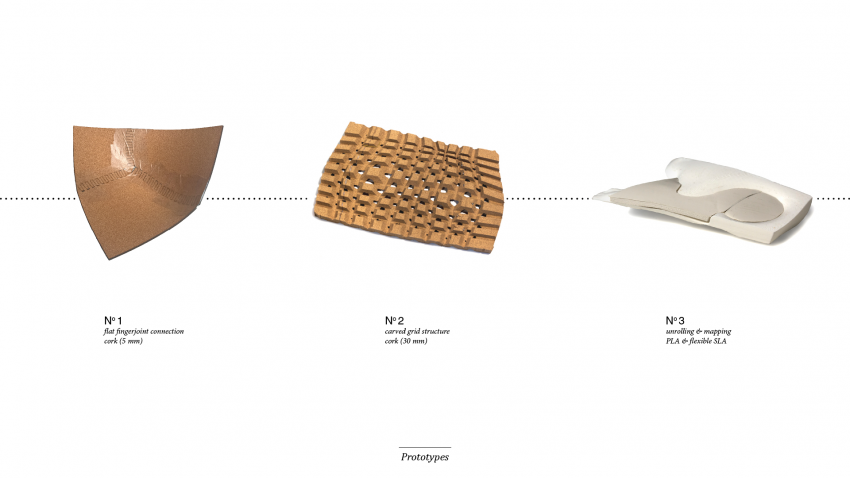

Prototyping to design Several prototypes have been made on the cork panels. These models where conducted in Styrofoam, cork and flexible SLA. Bending, connection and carving were tested in the prototypes.